What is the difference between mild steel and Corten Steel?

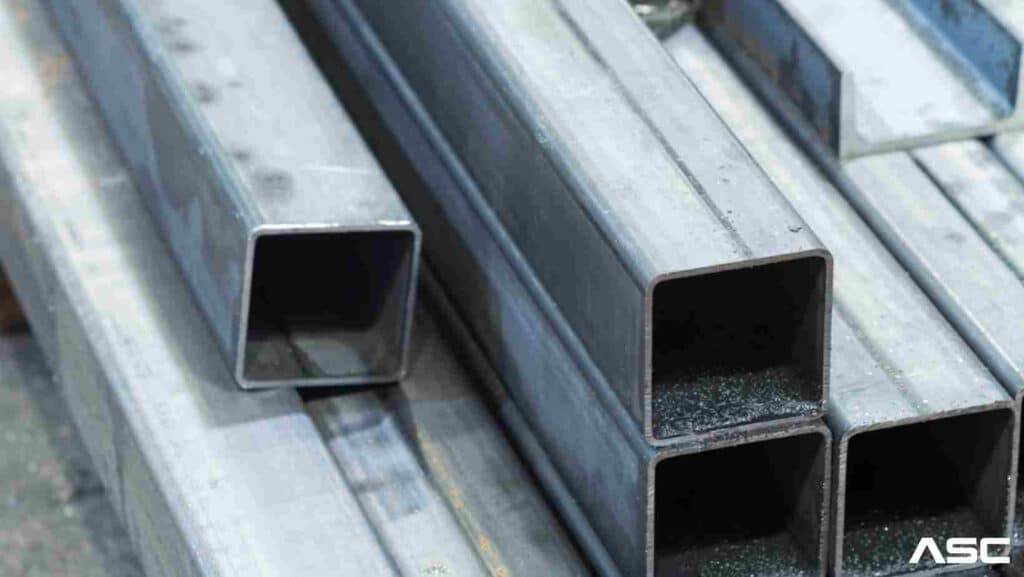

Plain carbon steel, or mild steel, is the most common type of steel in use today. Mild steel is more economical and once sealed, it will retain a rusted effect with a natural character called Penetrol. Low-carbon steel is malleable and ductile due to the 0.05-0.25% carbon content.

These seals prevent rust while maintaining the colour and appearance of the steel. The tensile strength of mild steel is relatively low, but it is cheap and easy to form. Its surface hardness can be increased by carburizing it.

Structural steel, for example, is often used when large amounts of steel are needed.

Corten steel is a type of alloy steel made by adding cobalt, nickel, and chromium to iron ore. Among other industries, it is used in construction and manufacturing.

Corten steel is commonly used for welding, but it can also be used for other purposes. For decades, it has been used in a variety of applications as one of the most popular types of steel.

Mild steel, on the other hand, is a more recent type of steel. Among the construction industry, it has been used for years in various applications.

Mild steel is an alloy steel with a lower softening point than corten steel, but a higher softening point than mild carbon steel. Applications include automotive parts, industrial machinery, and welding equipment.

Mild steel has a density of 7.85 g/cm3 (7850 kg/m3 or 0.284 lb/in3).

Speaking of Corten Steel, specialized Corten Steel is used for proper functioning. Cortensteeltube.com Is one leading Manufacturer, Supplier & Stockist Of Corten Steel ASTM A588 grade A plate sheet.

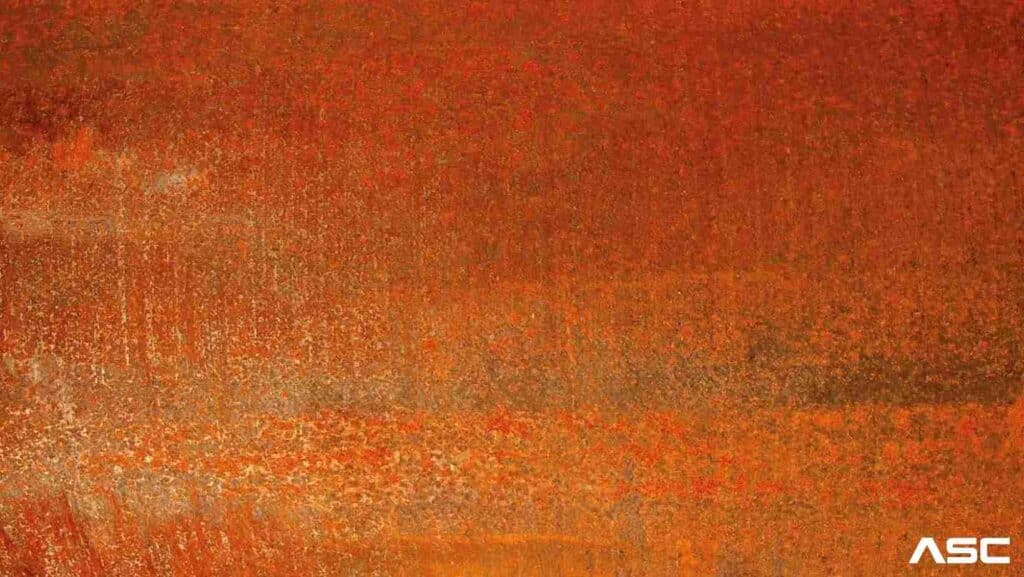

Weather-resistant steel called Corten steel (often called Cor-Ten) is more accurately termed an “atmospheric corrosion resistant steel”. Copper chromium alloy steels are more resistant to atmospheric weathering than unalloyed steels. A protective layer forms on the surface of steel when it is exposed to the weather.

Depending on how the alloying elements are distributed and concentrated, the protective layer has corrosion-retarding properties. As a result of the weather influencing the surface, the protective layer develops and regenerates continuously. To form the ‘protective’ coating, the steel is allowed to rust.

What is corten steel?

Corten steel is becoming increasingly popular among roll-formed product manufacturers. Its unique appearance and naturally oxidizing finish make it highly desirable for architectural projects. When exposed to the weather, COR-TEN steel forms a stable rust-like appearance and eliminates the need to paint.

Due to its increased resistance to atmospheric corrosion, weathering steel has a higher corrosion resistance than other steel. By forming a dark brown oxide layer over the metal, Cor-TEN resists corrosion caused by rain, snow, ice, fog, and other weather conditions. This inhibits deeper penetration and eliminates the need for painting and expensive rust-prevention maintenance. By allowing the steel to rust, a protective coating forms to slow the rate of corrosion in the future.

What is mild steel?

Known as “low carbon steel” in addition to mild steel, low carbon steel has a very low carbon content compared to other carbon steel. Mild steel is usually composed of 0.05% to 0.25% carbon. However, high-carbon steels are characterized by a carbon content between 0.30% and 2.0%. Mild steel has different carbon contents depending on its source. Steel that contains more carbon than that would be classified as cast iron.

Due to the fact that mild steel is not alloy steel, it does not contain high quantities of other elements besides iron; chromium, molybdenum, and other alloying elements do not make up mild steel. There are several properties that make it distinct from steels with high carbon and alloying elements due to its low carbon and alloying element content.

Cortetube.comnsteel is a leading supplier, stockist, manufacturer & exporter of Corten Steel ASTM A588 grade A plate sheet. Get in touch with us for the best rates & availability.

Leave A Comment