What’s the difference between Corten steel and stainless steel?

External architectural steel is typically available in three forms when designing outdoor spaces – Corten (WeDue to its rust-coloured finish, it has become popular among architects

Understanding the significant differences between these finishes is crucial, not just in terms of aesthetics, but also in terms of the myriad other factors that will determine a project’s success.

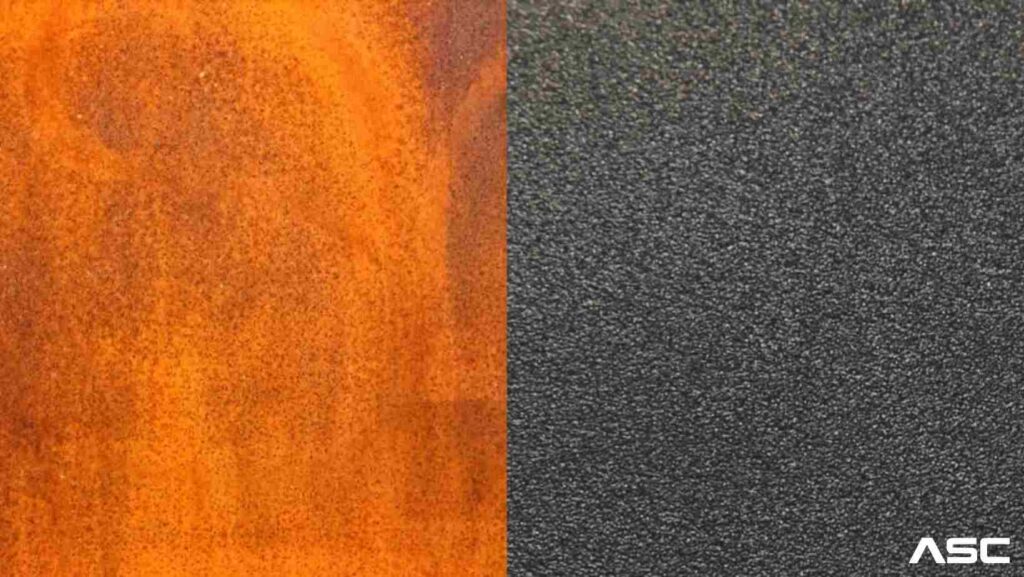

Corten steel is an exceptionally strong steel grade that was originally used in the American rail industry. Due to its rust-coloured finish, it has become popular among architects. Because it contains copper, nickel, chrome and titanium, it behaves quite differently than standard steel. These added elements cause the surface of the steel to oxidise when in contact with moisture, very similar to standard steel, but Corten self-seals once oxidation has taken place.

Steel will continue to oxidise until it disappears. The final appearance can take anywhere from 6 months to 2 years depending on the natural elements it is exposed to.The Duration periods Is different of If used in appropriate environments, Corten can be great, but there are many pitfalls to be aware of – make sure Corten Grade A is specified and research the environmental conditions.The Corten steel vs stainless steel cost is based on Weight of both material And their grades

Stainless Steel

Chromium, Copper, Titanium, Molybdenum, and a few others make stainless steel a highly corrosion-resistant metal alloy. Stainless Steel comes in many grades, but all Stainless Steels contain at least 11% Chromium. Stainless steel is popular for outdoor uses because of its corrosion resistance. It should be noted that it is stain ‘less’ rather than stain ‘free’.

The term ‘steel grades’ is frequently used when researching steel. Steel’s chemical composition is simply described here. For external architectural uses, Grade 304 and Grade 316 are the most common grades. The most common grade is 304, which contains 18% chromium.

A variety of finishes are available for Stainless Steel from an aesthetic standpoint. Below is a summary of the 5 most popular finishes used in outdoor architectural environments.

| ASTM Designation | Name | Description |

|---|---|---|

| 01 | Mill Finish | Matt, typically would be coated if visible. |

| 04 | Brushed Finish | Brushed lines in a parallel pattern. Not too reflective. |

| 06 | Satin Finish | A smoother surface than brushed finish due to the finer grit used on the finishing belt. |

| 07, 08 | High Polish | It is also known as a mirror finish, which is highly reflective and shiny. |

| 09 | Bead Blasted | Small Balls are fired at the Steel at high velocity to create a matt, slightly pitted finish. |

Leave A Comment