Aerospace and automotive industries use corten steel, a strong alloy of carbon and chromium. Wings, windscreens, body panels, etc. have all been made from it. This alloy is also used in radiators. The mechanical strength and durability of corten steel are superior to those of cast steel. It can withstand high loads without weakening and is quite corrosion-resistant. Using corten grades of steel in our products ensures that they will remain in working order for many years to come.

Together, corten steel is welded and riveted. A carbon steel core is surrounded by a layer of chromium. To prevent corrosion, the layers are nickel-plated. The thicknesses range from 0.005mm to 0.1mm (0/1mm) thick, based on the strength required for the application.

By extruding over the hot wire, corten steel is formed in a continuous layer so that each layer is uniform in thickness. Drilling and milling are used to finish the final details. These materials gain more strength, lightness, flexibility, and toughness through the die heat treatment process.

The demand for high-strength steel may increase in the future. There will be greater use of corten steel due to its ability to withstand higher temperatures and pressures than other steels.

How is corten steel made?

The purpose of this section is to explain how corten steel is made. The article explains how steel is made and what makes it special. It is hard and strong. Steel is heated in a furnace and then cooled in a quenching bath. Depending on the size of the piece, this process usually takes two or three days. The steel is brittle for about a day after this before it hardens again. Ferrous metals are sometimes used to make steel.

It is also known as cast iron or wrought iron, and it differs from other types of steel because the metal has been mixed with other materials. It is not heated in a furnace but rather mixed with chemicals to make it hard enough to use. It takes about a day to complete this process. Hardened steel can be used to make pipes, weapons, and tools, among other things. Water can hold its shape very well and it has good tensile strength. In addition, it is not easily corroded or rust-proofed when rust-resistant materials are used.

Benefits Of Corten Steel

As well as reducing overall material costs, Cor-ten Steel can be used for architectural cladding as well as artistic applications.

Low Maintenance

The only maintenance required when using exposed weathering steel is periodic cleaning and inspection. To clean rusted surfaces, rinse them with water to remove natural debris and contaminants. A strong rain can provide regular cleaning to weathering steel members if applied properly. Furthermore, scratches and dings are benefited by the oxide structure, which heals naturally without the need for replacement.

Long-Term Cost Savings & Performance

Various structures and buildings built nearly 50 years ago demonstrate the durability of the material, resulting in long-term cost savings. DOTs and transportation structures throughout the world use this material because of its long-term cost savings and durability. Additionally, this material’s living, protective properties eliminate the need for expensive painting and onsite paint maintenance. Corten steel is an ideal cladding material when future maintenance is difficult or dangerous, or when traffic disruption must be minimized.

Environmental Benefits

By reducing Volatile Organic Compounds (VOC) emissions from paint coatings and cleaning processes associated with painting, weathering steel provides LEED certifications for sustainable building. The fact that our product exceeds LEED requirements for MR 4.1/4.2, MR 2.1/2.2, and MR 5.2/5.2 credits, in addition to other green qualities like being 100% recyclable and made from recycled content, makes it an environmentally friendly product. (Environmental benefit information will be provided according to project specifications.)

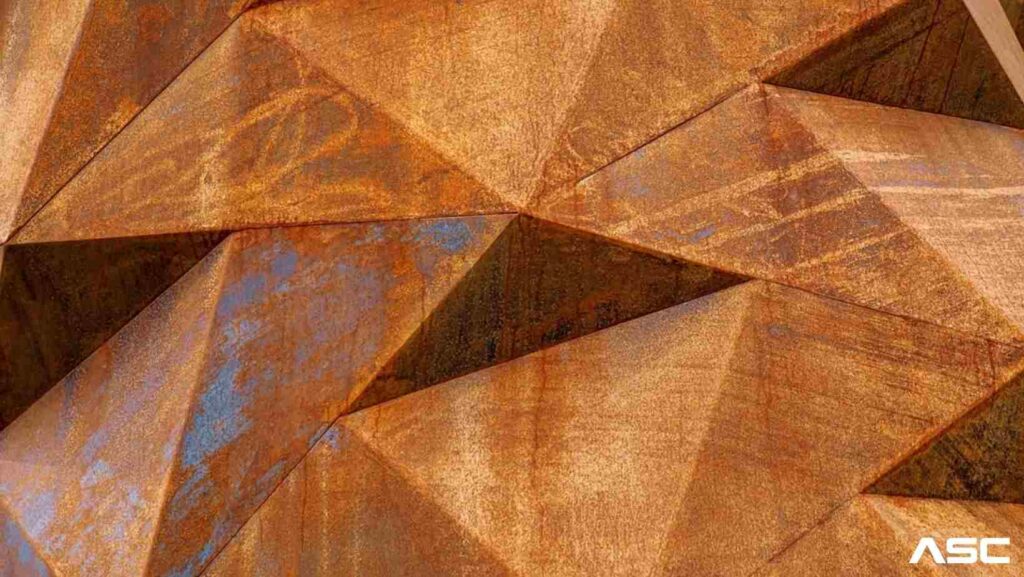

Dynamic Appearance and Texture

Weathering steel adds depth to a building’s appearance. The patina can change from dry to wet (and back again) multiple times a day, adding depth and wonder to the surface. Weathered steel becomes more than what was initially perceived. In time, you’ll begin to notice the subtle appearance hiding behind the exposed surfaces, waiting to be discovered.

There are very few materials with a depth that can be dramatically altered by the ambient environment. The patina continues to blend and improve with age, displaying deep tones and a variegated character. Oxide layers develop deeper and more earthy tones as they mature.

Minimizing Cost & Lead Time

In the most streamlined, minimal-cost application, raw corten steel will reduce the overall costs and lead times associated with cladding materials. The initial flash rust that develops when cladding raw corten steel will run off and bleed onto adjoining surfaces. A gutter or catch system can be incorporated into the design to hide or transfer loose ferrites. Our pre-weathered is designed to reduce run-off and staining associated with corten.

What Is Corten Steel?

One of the groups of ‘Weathering Steels’ developed for its superior corrosion resistance, Corten Steel is a low-alloy, high-strength outdoor steel. Once left to weather, it develops a rusty appearance, which eliminates the need to paint it.

In this context, ‘Corten Steel’ refers to both COR-TEN and generic grades of ‘weathering’ steels. Most landscape industry applications can benefit from this group of similar steels.

Rust forms a protective layer on the metal surface, preventing further corrosion and reducing glare. While simultaneously increasing the material’s life span, this process reduces the amount of maintenance required.

Nickel, copper, and chromium are alloyed to increase strength and corrosion resistance. Corten was originally used for coal carriages in the 1930s but is now used in a variety of outdoor applications. It can be incorporated into a wide range of architectural designs, including buildings, roofs, bridges, and sculptures.

Corten Steel oxidizes when exposed to the alternating wet and dry conditions that exist outdoors. By continuously regenerating, the rust layer develops into a patina layer that changes the color from orange to dark brown, which promotes corrosion resistance.

This process can take between 4 and 10 years, but more frequent wet and dry cycles will speed it up. Corten steel won’t prevent rusting, but it will reduce the amount of corrosion when applied properly.

Why is corten steel so popular?

The strength, durability, practicality, and aesthetic appeal of Corten contribute to its popularity. Corten is capable of resisting greater forces before buckling or breaking due to its tensile strength of 68-78 KSI compared to 45-64 KSI for galvanized steel sheets.

In most environments, corten is protected against corrosion by its naturally-occurring protective oxidized layer. The surface of Corten does not require painting or ongoing treatment. In the event that the oxidized layer is scratched and exposed to new steel, it will quickly oxidize and blend in with the rest of the surface.

A major reason for its popularity in landscape architecture must surely be its raw, natural beauty. It blends effortlessly with other natural materials such as wood and stone to provide a striking contrast to lush foliage.

How does corten steel gain its patina?

Depending on its grade, corten steel is a mixture of steel and alloys. When exposed to the elements, its dull, dark gray surface might appear as if a wrong product was supplied, but over time it will develop a patina that is unique to each piece. As humidity, heat, and airborne pollutants contribute to this natural palette, oxidation will be faster in more exposed locations and if water remains on the surface instead of draining.

Leave A Comment