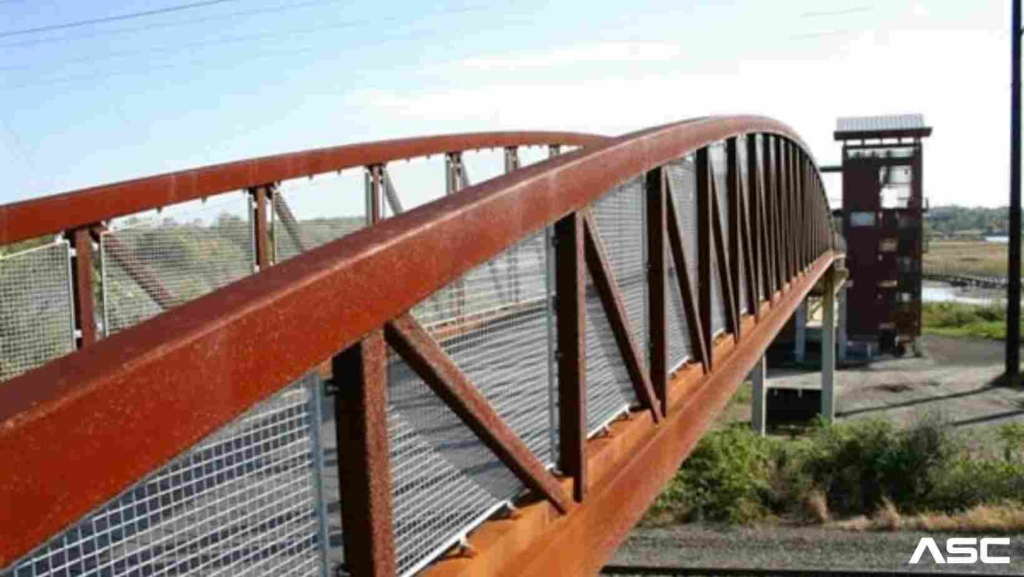

Have you ever seen a rusty bridge in your neighborhood or while traveling? In addition to pedestrian bridges and highway bridges, corten-equivalent corten steel is commonly used as an alternative. While conventional steel bridges take advantage of the latest advances in automated fabrication and construction techniques to provide economical solutions, corten steel bridges offer additional benefits.

Corten steel provides practical advantages over other metals for structures exposed to the elements, such as bridges.

A bridge constructed from unpainted corten steel can have a design life of 120 years with only minimal maintenance because the corrosion rate is so low. A well-detailed corten steel bridge can provide an attractive, very low maintenance, economical solution in many environments.

Corten steel is slightly more expensive than ordinary structural steel, but eliminating the paint system offsets the price difference. As a result, the initial cost of a corten steel bridge is very similar to that of a conventional painted steel bridge. An analysis of eight bridges in the UK illustrated this.

Speaking of Corten Steel, specialized Corten Steel is used for proper functioning. Cortensteeltube.com Is one leading Manufacturer, Supplier & Stockist Of Corten Steel ASTM A588 Grade A Plate And Sheet.

Corten steel bridges, however, have the added benefit of a lower overall life cycle cost. The minimal need for future maintenance of corten steel bridges reduces both the direct cost of maintenance operations and the indirect cost of traffic delays during maintenance.

This publication highlights the benefits of corten steel bridges, describes the limitations, and comments on both the material availability and the appearance of such bridges. It also provides advice on a range of issues including design and detailing, fabrication, and installation, and Corrosion rates that are higher than those anticipated at the design stage and require inspection, maintenance, and remedial measures.

Steels of this type are high strength low alloy steels that under normal atmospheric conditions exhibit enhanced resistance to rusting over ordinary carbon manganese steels. Wearing steels are generally specified to BS EN 10025-5: 2004, and have similar mechanical properties to conventional grade S355 steels to BS EN 10025-2: 2004. The most commonly used grade for bridgeworks in the UK is S355J2W+

In corten steel, rusting occurs in the same way, but the specific alloying elements in the steel produce a stable rust layer that adheres to the base metal and is less porous. Under alternate wetting and drying conditions, rust develops a protective barrier that prevents oxygen and moisture from reaching the surface.

In order for corten steel bridges to be safe and durable, a sufficient layer of corrosion protection must be created. The microclimate around the bridge, the time of wetness, the structural solution of the bridge, and the location and orientation of the steel surface within the bridge all influence the development of protective layers.

In this article, the focus is on the microclimatic effects of road traffic under the bridge. Experiments in situ are used to evaluate the effect of chloride deposition on corrosion products. We selected two bridges made of corten steel and crossed different types of obstacles for this experiment.

The relationships and dependencies between the measured parameters (deposition rate of chlorides, corrosion rates, thickness of corrosion products, and amount of chloride in corrosion products) are examined and discussed.

Cortensteeltube.com is a leading supplier, stockist, manufacturer & exporter of Corten Steel. Get in touch with us for the best rates & availability Of Corten Steel ASTM A588 Grade A Plate And Sheet.

Leave A Comment