Corten Steel Properties: The Ultimate Guide to This Versatile Material

Corten steel, also known as weathering steel, is a high-strength, low-alloy steel that is widely recognized for its unique properties and striking appearance. Originally developed to eliminate the need for painting, Corten steel has become a popular choice across various industries due to its excellent performance in tough environmental conditions.

In this blog, we’ll delve into the key properties of Corten steel and explore why it’s such a desirable material for construction, architecture, and beyond.

Corten steel derives its name from its two main properties: corrosion resistance and tensile strength. It forms a stable rust-like appearance after prolonged exposure to weather, which not only gives it an aesthetic appeal but also enhances its durability. The material was first developed in the 1930s by the United States Steel Corporation for use in railcars, but it has since found applications in architecture, landscaping, and industrial equipment

Key Properties of Corten Steel

1. Corrosion Resistance

Corten steel’s most notable property is its ability to resist corrosion. When exposed to the elements, it develops a protective oxide layer (patina) that prevents further rusting. Unlike regular steel, this patina layer makes Corten steel highly resistant to atmospheric corrosion, especially in outdoor applications.

2. High Tensile Strength

Corten steel offers superior tensile strength compared to traditional steels. This makes it an ideal material for structural applications where strength is critical. It can withstand significant stress and strain, ensuring longevity and safety in demanding environments.

3. Weather Resistance

Thanks to its patina layer, Corten steel performs exceptionally well in harsh weather conditions. It is particularly effective in resisting damage caused by rain, snow, and fluctuating temperatures, making it a preferred choice for outdoor installations.

4. Low Maintenance

One of the biggest advantages of Corten steel is its low maintenance requirement. Since it naturally forms a protective layer, there is no need for additional coatings or paint, reducing long-term upkeep costs.

5. Aesthetic Appeal

Corten steel is popular in modern architecture and landscaping due to its warm, earthy tones and industrial look. Its unique, rust-like finish creates a timeless and organic appearance that blends seamlessly with both natural and urban environments.

6. Cost-Effectiveness

Although the initial cost of Corten steel may be higher than regular steel, its long lifespan and minimal maintenance needs make it a cost-effective choice over time. Its durability reduces replacement and repair expenses, offering significant savings in the long haul.

Corten Steel Properties

Corten steel naturally undergoes a chemical process that creates a new surface composition that offers more atmospheric corrosion protection than other steels can provide.

Corten steel also provides the following properties:

- Paint Durability— While many manufacturers prefer Corten’s rustic look as it is, it can be painted in the same manner other steels are painted in, but it requires a less frequent repainting cycle due to its lower rust rate.

- Weldability—Since it has a low carbon content, the steel remains pliable enough for welding.

- Workability—Corten steel can be cold-formed, hot-formed, and gas-cut, making it easy to work with no matter what the project requirements are.

- Reliability—It displays 2-8 times more anti-corrosive resistance than regular steel, is 1 ½ – 10 times more paintable than common carbon steel, and has a tensile strength of no less than 445 MPa, making it a high-performance, long-lasting material for steel parts.

| Property | Description | Value or % |

|---|---|---|

| Tensile strength | High and can withstand significant stress without deformation | 470 – 630 MPa |

| Yield strength | Strong and can maintain structural integrity and its original shape under stress | 310 – 345 MPa |

| Elongation | Excellent and forms an external oxidized layer or patina to protect from rust and corrosion | 6 – 12 months for the initial layer of patina |

| Corrosion resistance | High and allows the steel to stretch without breakage | ~20% |

Explore Corten Steel Properties—Perfect for Projects That Need Strength and Style.

Corten Steel refers to the chemical composition of corten steel, allowing it to exhibit increased resistance to atmospheric corrosion compared to other steels.

The corrosion-retarding effect of the protective layer is produced by the particular distribution and concentration of alloying elements in it. It still needs to be determined how exactly the patina formation differs from usual rusting, but it’s established that drying of the wetted surface is necessary and that copper is the most important alloying element.

| Grade | C | Si | Mn | P | S | Cr | Cu | V | Ni |

|---|---|---|---|---|---|---|---|---|---|

| ASTM A242 | 0.12 | 0.25–0.75 | 0.20–0.50 | 0.01–0.20 | 0.030 | 0.50–1.25 | 0.25–0.55 | 0.65 | |

| ASTM A588 | 0.16 | 0.30–0.50 | 0.80–1.25 | 0.030 | 0.030 | 0.40–0.65 | 0.25–0.40 | 0.02–0.10 | 0.40 |

Corten Steel Physical Properties

| Weather Resistant Steel | Standard | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation in 2 inches (min.) % |

|---|---|---|---|---|

| CORTEN A | US Steel | 470 – 630 | 355 | 20 |

| IRSM 41-97 | Indian Railways | 480 min | 340 min | 21 |

| ASTM A 588 | ASTM | 485 min | 345 min | 21 |

Corten Steel Mechanical Properties

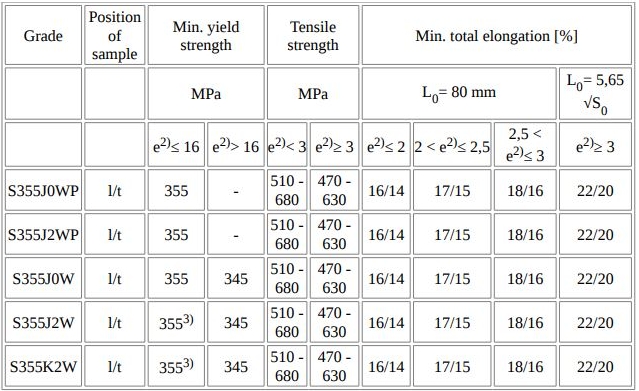

The mechanical properties of Corten Steel are based on the thickness and the alloy being used. Depending on the grade of weathering steel.

Corten Steel Equivalent Material

| Grade | Thickness (mm) Strip Products | Plate Products | Yield Strength Rel N/mm² Minimum | Tensile Strength Rm N/mm² Minimum | Elongation A50 % Minimum |

|---|---|---|---|---|---|

| Corten A | 2-12 | 6-12 | 345 | 485 | 20 |

How is Corten Steel Made?

The corten steel manufacturing process begins with a blending of three primary plates of steel—copper, chromium, and nickel—along with other alloying elements like phosphorus, silicon, and manganese.

Very little carbon is used during the mixing process—less than 0.2-0.3 percent—to ensure pliability, strength, and toughness.

Combining these specific metals and elements results in a 1/4th inch thick sheet that is ductile enough to be formed into almost any desired shape.

The real magic of the corten steel process, however, occurs after the initial mixing takes place and during its natural weathering cycle.

Advantages of Corten Steel

- Longevity: It is strong, durable, and lasts for years, making it cost-effective in the long run

- Low on maintenance: Once installed, minimum investment is required to upkeep the structure due to its self-protective oxide layer

- Aesthetic appeal: A naturally rustic look that’s striking and poses an industrial contrast to natural landscapes

- Easy to weld and give shape: Its high tensile strength and weldability allow for it to be shaped into diverse shapes (e.g., architectural, infrastructural, light, and heavy-load projects)

- Sustainable: Is easily recyclable making it an eco-friendly material to work

Applications of Corten Steel

Corten steel’s impressive properties make it suitable for a variety of applications, including:

- Architecture: Facades, cladding, and roofing materials for a modern industrial look.

- Landscaping: Garden sculptures, planters, retaining walls, and fencing.

- Bridges and Infrastructure: Durable and weather-resistant structures.

- Outdoor Furniture: Benches, tables, and decorative pieces.

- Industrial Use: Railcars, shipping containers, and storage tanks.

Conclusion

Corten steel combines strength, durability, and beauty, making it an exceptional material for a wide range of applications. Its unique ability to withstand harsh environments without losing its aesthetic charm ensures it remains a popular choice for modern construction and design. If you’re considering materials for your next project, Corten steel deserves a top spot on your list. To learn more about Corten Steel, feel free to contact Corten Steel Tube.

FAQ’s

Corten steel is durable, low maintenance, and has a high tensile strength. It’s also resistant to corrosion and can be used in a variety of architectural and structural applications.

Corten A is lower in carbon, manganese, and silicon, and is often used for outdoor sculptures and aesthetic fascias. Corten B has more carbon than manganese and is often used for heavy-duty structures.

Corten steel is designed to rust and form a protective layer called a patina. This patina is less porous than the rust that forms on other steels, and it protects the steel from further corrosion.

Yes, Corten steel is heat resistant and maintains stability in moderate to high temperatures, making it suitable for outdoor and fluctuating temperature conditions. However, it’s not ideal for extremely high-heat environments like furnaces.

Contact Our Expert Team Now

Corten Steel Tube is a leading supplier of high-quality Corten steel products in India. We offer a wide range of Corten steel sheets, plates, and custom sizes, supported by cutting-edge fabrication and processing services to meet your project needs.