APH (Air Preheater) Tubes Corten Steel Manufacturer & Supplier

Corten Steel Tube is a top manufacturer, supplier, and exporter of air preheater tubes. We pride ourselves on providing the highest quality air preheater tube while being very competitive in pricing.

The Air Preheaters (APH) is an important and common part of many industrial processes. Air preheaters are heat exchangers that heat air used in boilers, furnaces, and kilns, for combustion of fuel. Air preheaters provide an opportunity to utilize exhaust gas heat, reducing energy waste and improving thermal efficiency of the boiler, etc.

We produce our APH Tubes to exacting quality protocols, using raw materials from reputable sources and many of the latest manufacturing processes. All our tubes are inspected to the highest quality certifications national and international. We recognize that all customer requirements are unique and that is why we carry the largest selection of APH Tubes in many shapes, sizes and wall thicknesses.

We are also willing to assess each of our customers’ needs to build to specifications. All of this at competitive pricing.

Features of APH Tubes

- Available in welded or seamless ends in hot rolled or cold drawn forms.

- Designed to meet elongation, hardness, yield strength, and tensile strength requirements.

- Size and quality depend on the boiler design, fuel type, and operational conditions.

Applications of Air Preheater Tubes

Our APH Tubes are widely used in:

- Power Plants

- Process Industries like Chemical, Sugar, and Steel

- Cooling Towers

- Air Heaters and Super Heaters

Quality and Testing of APH Tubes

To ensure the highest standards, our APH Tubes undergo:

- Third-Party Inspections

- PMI Testing

- Raw Material Testing

- Corrosion Resistance Testing

- Flaring/Flattening Testing

APH Tubes Price

At Corten Steel Tube, we offer competitive pricing on high-quality APH Tubes, ensuring value for money without compromising on durability and performance. Contact us today for a quote!

Contact Corten Steel Tube today for the best deals and competitive quotes on high-quality

Corten Steel APH Tubes. Don’t miss out—get your offer now!

Types of Air Preheaters and Their Uses

Air preheaters (APH) are heat exchange devices used in boilers and furnaces to improve thermal efficiency by heating the incoming air using exhaust gases. There are mainly three types of air preheaters:

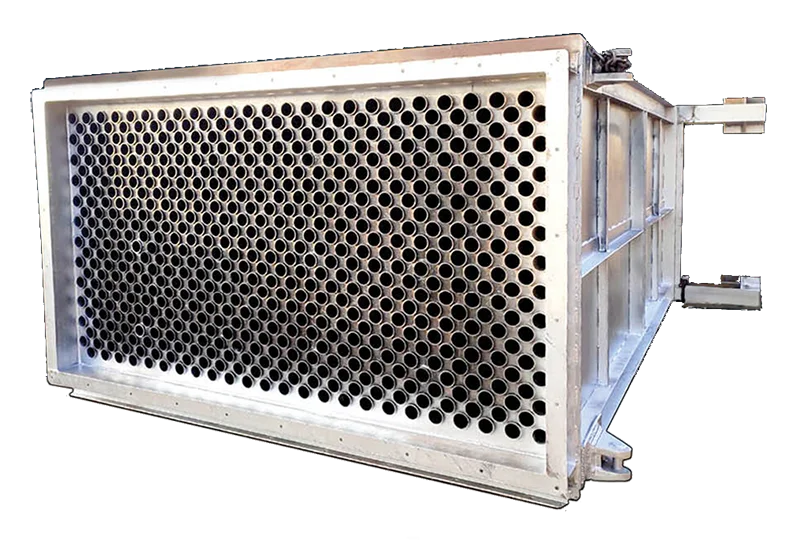

Tubular Air Preheater

| Structure | Made of straight or bent tubes arranged in bundles. |

|---|---|

| How It Works | Hot flue gases pass over the tubes while cold air flows inside them, gaining heat. |

| Uses | Frequently found in industrial boilers and major power plants. |

| Advantages | Benefits include ease of maintenance, simplicity in design, and suitability for high-pressure systems. |

Regenerative Air Preheater (Rotary Type)

| Structure | Consists of a rotating drum with heat-absorbing plates or elements. |

|---|---|

| How It Works | The drum transfers heat from the flue gas to the air by rotating between streams of air and flue gas |

| Uses | Commonly found in thermal power plants. |

| Advantages | Efficient heat transfer, small size, and high efficiency |

Plate-Type Air Preheater

| Structure | Uses stacked metal plates to separate and transfer heat between gas and air. |

|---|---|

| How It Works | Air flows on one side of the plates while hot gases flow on the other. |

| Uses | Fits boilers that are small to medium in size. |

| Advantages | Compact, lightweight, and efficient for light- to medium-duty uses. |

APH Tube Specification

Air Heater Tubes Specification includes thickness ranging from 0-10mm, lengths of 5-15 meters, made from high-quality polished Corten steel for durable performance.

| Thickness | 0-10mm |

|---|---|

| Length | 5-15 m |

| Material | CORTEN STEEL |

| Features | High Quality |

| Finishing | Polished |

Grades of ERW APH Tubes

- BS: 3059 (Pt-I & II)

- BS: 6323 (Pt-V)

- ASTM: A-178 / A-214 / A-333 / A-334

- IS: 1914 (Pt-IV)

- IS: 2416 (Pt-IV)

- IS: 11714 (Pt-III)

Corten Steel APH Tube Chemical Properties

| Si % max. | C % max. | Mn % | Z% | S % max. | P % | N % max. | Cr % | V% | Cu % | Ni% | Mo% | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| According to EN 10027-1 & CR 10260 | ||||||||||||

| S235J2W | 0.40 | 0.13 | 0.20-0.60 | – | 0.03 | 0.04 | – | 0.40-0.80 | – | 0.25-0.55 | 0.65 | – |

| S235J0W | 0.40 | 0.13 | 0.20-0.60 | – | 0.04 | 0.04 | 0.01 | 0.40-0.80 | – | 0.25-0.55 | 0.65 | – |

| S355J2WP | 0.75 | 0.12 | 1.00 | – | 0.03 | 0.06-0.15 | – | 0.30-1.25 | – | 0.25-0.55 | 0.65 | – |

| S355J0W | 0.75 | 0.12 | 1.00 | – | 0.04 | 0.06-0.15 | 0.01 | 0.30-1.25 | – | 0.25-0.55 | 0.65 | – |

| S355J2W | 0.50 | 0.16 | 0.50-1.50 | 0.15 | 0.03 | 0.03 | – | 0.40-0.80 | – | 0.25-0.55 | 0.65 | 0.30 |

| S355J0W | 0.50 | 0.16 | 0.50-1.50 | 0.15 | 0.04 | 0.04 | 0.01 | 0.40-0.80 | – | 0.25-0.55 | 0.65 | 0.30 |

| S355K2W | 0.50 | 0.16 | 0.50-1.50 | 0.15 | 0.03 | 0.03 | – | 0.40-0.80 | – | 0.25-0.55 | 0.65 | 0.30 |

| According to ASTM & ASME Specn. | ||||||||||||

| A 588 Gr. B | 0.15- 0.50 | 0.20 | 0.75-1.35 | 0.05 | 0.04 | – | 0.40-0.70 | 0.01- 0.10 | 0.20-0.40 | |||

| A 588 Gr. A | 0.3- 0.65 | 0.19 | 0.80-1.25 | 0.05 | 0.04 | – | 0.40-0.65 | 0.02- 0.10 | 0.25-0.40 | |||

| A 588 Gr. C | 0.15- 0.40 | 0.15 | 0.80-1.35 | 0.05 | 0.04 | – | 0.30-0.50 | 0.01- 0.10 | 0.20-0.50 | |||

| A 242 Type-1 | – | 0.15 | 1.00 | 0.05 | 0.15 | 0.20 min. | ||||||

| A 588 Gr. K | 0.25- 0.50 | 0.17 | 0.50-1.20 | Cb-0.005 -0.05 | 0.05 | 0.04 | – | 0.40-0.70 | – | 0.30-0.50 | ||

| A 242 Type-2 | – | 0.20 | 1.50 | 0.05 | 0.04 | 0.20 min. | ||||||

| According to IS STD. | ||||||||||||

| IRSM-41 | 0.30- 0.50 | 0.10 | 0.25-0.45 | – | 0.03 | 0.075-0.14 | – | 0.35-0.49 | 0.05 | 0.30-0.60 | 0.28- 0.49 | 0.05 |

APH Tube Material Equivalent

| Material # | ASTM | SEW 087 | EN 10155 | UNI | NFA 35-502 | BS 4360 | JIS G3114 |

|---|---|---|---|---|---|---|---|

| 1.8967 | – | – | S355K2G2W | – | – | – | – |

| 1.8945 | – | E 36 WA 3 | S355J0WP | WR 50 A | Fe 510 C1K1 | – | – |

| 1.8961 | – | WTSt 37-3 | S235J2W | Fe 360 DK 1 | E 24 W 4 | – | – |

| 1.8959 | A 588 – A 242 Gr. 1 | – | S355J0W | Fe 510 C2K1 | E 36 WB 3 | WR 50 B | SMA 50 AW |

| 1.8946 | A 242 Type 1 | – | S355J2WP | Fe 510 D1K1 | E 36 WA 4 | – | – |

| 1.8965 | – | – | S355J2G2W | – | – | – | SMA 50 CP |

| 1.8963 | A 588 Gr. A | WTSt 52-3 | S355J2G1W | Fe 510 D2K1 | – | WR 50 C | to |

| 1.8966 | A 709 Gr. 50 W | – | S355K2G1W | – | E 36 WB 4 | – | – |

Boiler APH Tube Mechanical Properties

| Metric | Imperial | |

|---|---|---|

| Ultimate Tensile Strength | 483 MPa | 70,000psi |

| Density | 7.75 g/cc | 0.28 lb/in3 |

| Yield Tensile Strength | 345 MPa | 50,000psi |

APH Tube Size Chart

| Size (Nominal Diameter) | Typical Wall Thickness | Common Applications |

|---|---|---|

| 1/2 inch | 1.5 mm to 3 mm | Small-scale air preheaters |

| 1 inch | 2 mm to 4 mm | Medium-sized industrial applications |

| 1.5 inch | 2.5 mm to 4.5 mm | Larger air preheaters for industrial use |

| 2 inch | 3 mm to 5 mm | High-capacity preheaters |

| 2.5 inch | 3.5 mm to 5.5 mm | Heavy-duty air preheaters |

| 3 inch | 4 mm to 6 mm | Large industrial systems |

| 4 inch | 4.5 mm to 7 mm | High-volume air preheaters |

| 6 inch | 5 mm to 8 mm | Large-scale and high-pressure systems |

| 8 inch | 6 mm to 10 mm | Heavy industrial applications |

Other Types Of Air Pre Heater Tubes

| Air Pre Heater Tubes Stockholder | APH ERW Tubes Supplier | APH IBR ERW Tubes |

| Stainless Steel Air Pre Heater Tubes Dealer | Carbon Steek APH Pre Heater Tubes | Corten Steel APH Tubes |

| Air Pre Heater Tubes Suppliers | Air Pre-Heater & Indian Boiler Regulation Tubes | APH ERW Tubes Stockist of TATA Steel |

| Air Pre Heater Tubes Stockholder | Air Preheater Tubes Stocks | Corten Steel APH ERW Tubes Supplier of TATA Steel |

| Air Pre Heater Tubes Distributors | Mild Steel Air Preheater Tubes | Boiler Air Pre-Heater Tubes |

| Air Pre Heater Tubes Manufacturer | Air Pre-Heater Corten Steel Tube Stocks | Corten Steel Air Pre Heater Boiler Tubes |

Function of Corten (Core 10) APH Tubes in Boilers

- Energy Efficiency: By preheating the combustion air, Corten APH tubes reduce the amount of energy required to raise the air temperature to the desired level, improving the overall efficiency of the boiler system.

- Reduced Emissions: Corten APH tubes help lower flue gas temperatures, which in turn reduces the emission of pollutants, contributing to cleaner energy production.

- Fuel Savings: The improved efficiency of the boiler, driven by the use of Corten APH tubes, results in significant cost savings by lowering fuel consumption.

FAQs for APH (Air Pre-heater)Tubes

Air Preheaters (APH) are Shell and Tube Heat Exchangers that are used to heat the air before it goes into the boiler or furnaces/kilns to burn fuels. The main job of an air pre-heater is to take heat from the flue gases coming out of the boiler.

Air Pre-heaters are basically heat-exchangers installed in the exit flus gas duct of the boiler. The purpose of the air preheater is to recover the heat from the boiler flue gas which increases the thermal efficiency of the boiler by reducing the useful heat lost in the flue gas.

Core 10 APH tubes enhance boiler efficiency by preheating combustion air, reducing energy and fuel consumption. They lower flue gas temperature, minimize heat loss, and reduce emissions, promoting eco-friendly operation. These tubes optimize combustion, ensuring cost savings and improved performance, making them vital for efficient boiler systems in industrial applications.

The air preheater is positioned between the flue gas outlet (chimney) and the air inlet (economizer) in a boiler system. It reduces flue gas temperature from 400°C to 240°C, significantly enhancing boiler efficiency by up to 10%, optimizing energy use, and lowering operational costs.

Cor-Ten steel APH tubes typically have an outer diameter ranging from 15.88 mm to 127 mm with a wall thickness of 1 mm to 6.5 mm. The standard length can be customized as per your needs, with lengths going up to 12 meters. All dimensions, including diameter, thickness, and length, are fully customizable. Simply share your specific requirements with the supplier to get the perfect size for your project.

Air preheaters improve thermal efficiency by recovering heat from flue gases, reducing fuel consumption, operating costs, and emissions, while optimizing combustion processes.

Dubai, Abu Dhabi, Sharjah, Delhi, Mumbai, Bangalore, Chennai, Hyderabad, Kolkata, Pune, Jaipur, Ahmedabad, Singapore, Sydney, Melbourne, Brisbane, Adelaide, Perth, London, Manchester, Glasgow, Toronto, Vancouver, Calgary, Montreal, Ottawa, Edmonton, Dublin, New York, Los Angeles, Chicago, San Francisco, Washington, Las Vegas, Miami, Boston, Seattle, Houston, Atlanta, Dallas, Orlando, San Diego, Phoenix, Austin, Denver, San Jose, Portland, Philadelphia, Minneapolis, Baltimore, Sacramento, Salt Lake City, Raleigh, Nashville, Cape Town, Johannesburg, Jakarta, Surabaya, Bandung, Lombok, Kuala Lumpur, George Town, Malacca, Kota Kinabalu, Manila, Cebu City, Davao City, Quezon City, Makati, Taguig.

United Arab Emirates (UAE), India, Singapore, Australia, United Kingdom (UK), Canada, South Africa, Ireland, Indonesia, Malaysia, Philippines, USA.

Contact Our Expert Team Today

At Corten Steel Tube, we specialize in providing high-quality Air Pre Heater (APH) Tubes to your specific needs. Our team is ready to assist you with product selection, customization, and any queries you may have to ensure a smooth experience from start to finish.