With laser cutting metal, steel sheets are cut and shaped into different shapes and sizes. In addition to being used in the construction industry, it is also used in the manufacture of furniture, furniture parts, motorcycles, boats, and the automotive industry as well. Hence, we are able to provide you with a top-quality laser cutting machine with a price-competence ratio that comes preassembled and ready to use.

Following machines are used to cut corten steel plate :

Fiber laser metal sheet cutting machines

Metal sheet&tube laser cutting machines

Tube laser cutting machines

Using lasers to cut Corten Steel will provide greater durability and cutting accuracy than using a knife, which will be discussed in this article: The benefits of cutting Corten Steel with lasersCutting with a laser will provide greater durability and cutting accuracy than using a knife. As a result, laser cutters can focus their beams of light on specific areas to produce clean, controlled cuts in metal.

In large-scale machining operations, precision is particularly useful when large amounts of material need to be removed quickly. The same applies to cutting materials that are not susceptible to contamination when cut with a knife. By using a laser cutter, you can prevent even the slightest mistake in your cuts, and this will result in a better product since you will remove less material than if you were using a knife.

Using an electric saw can provide the same benefits, but with the added benefit of being able to handle a smaller surface area. You can also use high energy when cutting with a laser. Industrial lasers, for example. As the energy is focused on the metal, it is possible for the beam to permeate through layers of material. Borehole drilling is said to be more accurate than any other method of cutting due to the use of high-energy lasers. This can create dust and debris that can be dangerous when working with lasers. It is not recommended to use lasers on thick materials such as stone or marble.

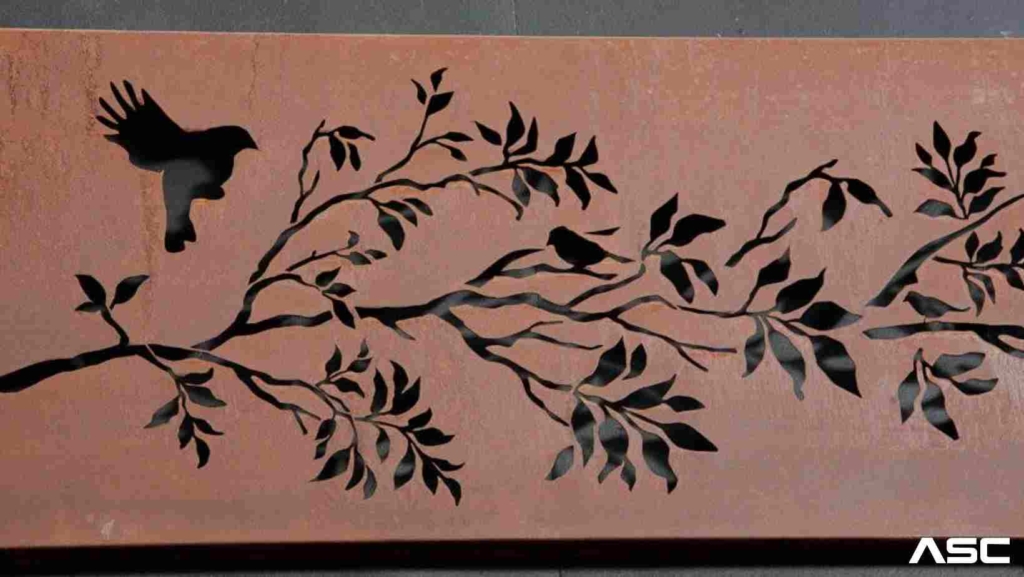

However, corten steel’s lack of versatility has limited its use. Laser cutters can be used to cut corten steel panels to solve the problem. It is, however, impractical for most people because it requires a lot of effort and time to prepare the panels for laser cutting. This project was inspired by traditional welding techniques. Laser energy is used to weld parts together using this welding technique.

With high-temperature lasers, heat can be generated, which causes friction and molten metal to escape from the part being welded. You must know how to use a laser cutter if you plan to use one for your projects. This project involves laser cutting corten steel panels and welding them together. An AXE servo motor is connected to a series of five servos in a series, and all servo motors are controlled by the motor controller on the circuit board.

The best way to overcome this problem is to understand how corten steel can be cut with laser cutting machines and what the benefits are. Since corten steel is a very heavy metal, it is somewhat difficult to cut. Using the right equipment and following the correct instructions could overcome this issue.

Check out our page on laser cutting machines if you are unsure what type you need. Laser cutting machines are essential tools for a laser cutter’s toolbox. It explains how the machine works, how it is used, and the advantages of using it. With it, you can create steel that is resistant to laser cutting.

In the absence of this technology, it would be impossible to manufacture strong, durable steel for aircraft parts or in building construction. Choosing a laser cutting machine that can cut easily and cleanly is also important. Check out our pages on how to make a good blade and how to sharpen it properly. There are two main types of laser cutting machines available. As a result of optical technology, the beam of light can be focused.

Leave A Comment