How heavy is Corten steel?

Corten steel, also known as weathering steel, has gained popularity in architectural and outdoor design due to its unique appearance and durability. But just how heavy is this material? Let’s explore the weight of Corten steel and its implications for various applications.

Understanding Corten Steel

Corten steel is a high-strength, low-alloy steel that contains copper, chromium, and nickel. Its distinctive feature is the development of a protective rust layer (patina) over time when exposed to the elements. This patina not only adds to its aesthetic appeal but also acts as a barrier against further corrosion.

Weight of Corten Steel ?

The weight of Corten steel depends on several factors:

- Thickness: Thicker Corten steel panels will naturally weigh more than thinner ones. Common thicknesses range from 1.5 mm to 50 mm (0.06 inches to 2 inches).

- Panel Size: Larger panels will be heavier. Architects and designers often choose Corten steel for large-scale installations such as building facades, retaining walls, and sculptures.

- Density: The density of Corten steel is approximately 7.85 g/cm³ (0.283 lb/in³). This value remains relatively consistent regardless of the specific alloy composition.

What is the unit weight of corten steel ?

Calculating Weight

To calculate the weight of a Corten steel panel, use the following formula:

[ \text{Weight (kg)} = \text{Area (m²)} \times \text{Thickness (mm)} \times 7.85 ]

Here’s a step-by-step breakdown:

- Measure the area of the panel (length × width) in square meters (m²).

- Determine the desired thickness in millimeters (mm).

- Multiply the area by the thickness and then by the density (7.85 g/cm³) to get the weight in kilograms (kg).

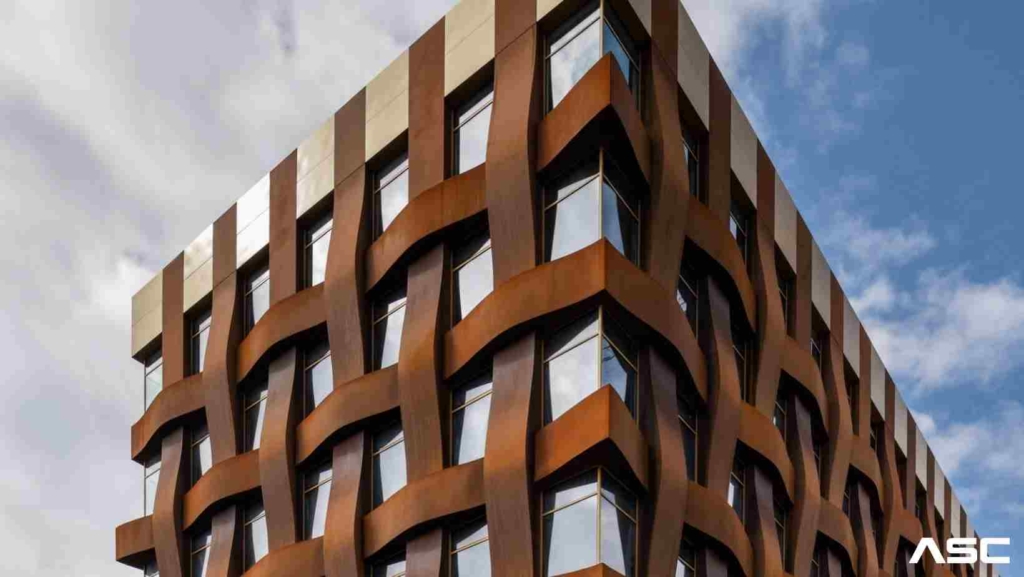

Corten Steel Applications

- Architectural Cladding: Corten steel panels are commonly used for building facades, exterior cladding, and roofing. Their weight affects installation logistics and structural considerations.

- Garden Sculptures and Landscaping: Corten steel sculptures and planters add an artistic touch to outdoor spaces. The weight influences placement and stability.

Retaining Walls and Fences: Corten steel’s durability makes it suitable for retaining walls and fencing. The weight affects installation and foundation requirements.

Corten Steel Handling and Installation Tips

- Teamwork: Due to its weight, handling Corten steel panels often requires a team effort.

- Lifting Equipment: Use appropriate lifting equipment (such as cranes or forklifts) for large panels.

- Surface Protection: Protect surfaces during transport to prevent scratches or damage.

Conclusion

Corten steel’s weight varies based on thickness and panel size. Whether you’re designing an architectural masterpiece or a small garden feature, understanding its weight is crucial for successful implementation. Embrace the beauty of Corten steel while appreciating its practical considerations!

Leave A Comment